1. Contactless processing, with no external force on welded parts.

2. Laser energy is highly concentrated, with minimal thermal impact and thermal deformation.

3. Can weld high melting point, refractory, and difficult to weld metals, such as titanium alloys, aluminum alloys, etc. Can achieve welding between certain dissimilar materials.

4. The welding process does not pollute the environment and can be directly welded in the air, making the process simple.

5. Small solder joints, narrow welds, neat and beautiful appearance, no need for treatment or simple processing steps after welding. The weld seam has a uniform structure, fewer pores, and fewer defects, which can reduce and optimize the impurities of the base material. The mechanical strength of the weld seam is often higher than that of the base material. Laser welding has superior mechanical, corrosion resistance, and electromagnetic properties compared to conventional welding methods.

6. Laser can be precisely controlled, with small focusing points and high-precision positioning, achieving precision machining.

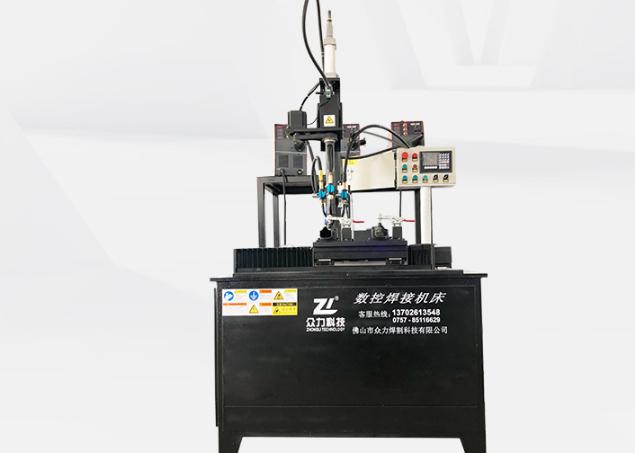

7. Easy to cooperate with computer numerical control systems, robotic arms, and robots to achieve automatic welding and improve production efficiency.

Therefore, using all aluminum whole plate welding has advantages such as high precision, high efficiency, high strength, and timeliness, ensuring quality, output, and delivery time. Currently, laser welding has become a highly competitive processing method in the precision machining industry, widely used for spot welding, overlay welding, and sealing welding of workpieces with special requirements in industries such as machinery, electronics, batteries, aviation, and instruments.

Article by: All aluminum whole plate welding http://m.writenet.cn Provided by Foshan Zhongli CNC Welding and Cutting Technology Co., Ltd., this article does not represent the views of our website